How is Bamboo Panel Made?

Jan 5, 2026, 15:30 PM

Bamboo panel manufacturing embodies sustainable practices. The material seldom requires replanting, grows quickly, and has the potential to reduce deforestation and preserve hardwood forests. It offers an ecologically sound option to consumers who are mindful of their environmental footprint, combining functionality, beauty, and the spirit of conservation.

Harvesting

Bamboo is a fast-growing grass that can reach maturity in 3 to 5 years, making it a highly renewable resource. The bamboo culms (stems) are harvested by cutting them near the base, leaving the root system intact to encourage regrowth and prevent soil erosion.Processing

After harvesting, the green outer layer of the bamboo culms is removed, and the inner material is cut into strips. The natural curvature of the bamboo is flattened through a mechanical process. Depending on the desired thickness of the final product, these strips can be varied in width and thickness.Boiling

To increase durability and reduce the risk of pest infestations, the bamboo strips undergo a treatment process. This usually involves boiling or steaming to remove sugars and starches, which attract insects and can lead to decay. Some methods also involve using natural, non-toxic borate solutions as a preservative.Drying

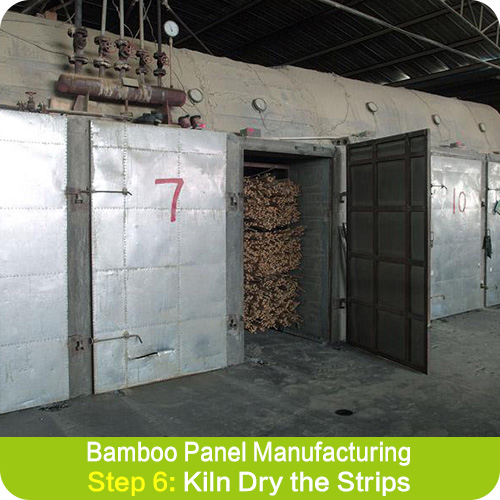

The treated bamboo strips are then dried to reduce their moisture content. Proper drying is essential to prevent warping and cracking of the panels. This can be done either naturally, by air-drying, or more quickly in drying kilns.Milling

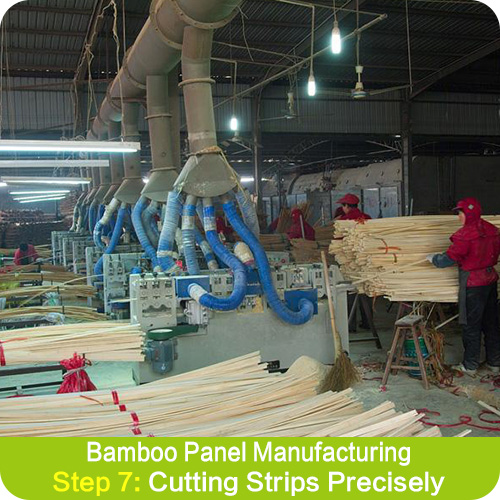

The split strips undergo milling to smoothen them and ensure uniform thickness and width. This step includes planing and sanding, processes that contribute to a flat surface free of splinters or rough edges.Lamination

The bamboo strips are glued together under pressure to form panels. The strips can be aligned either horizontally or vertically, affecting the panel's appearance. Horizontal alignment shows the bamboo "knuckles" or nodes distinctly, while vertical alignment offers a more uniform look. The type of adhesive used is crucial for the panel's environmental footprint; some manufacturers opt for eco-friendly adhesives to maintain the bamboo's natural appeal.Sanding

The bamboo panel sheets are then sanded to create a smooth, even surface that is ready for finishing. Finishes might vary from matte to glossy, and some products can be pre-finished with a UV inhibitor or a waterproofing agent to enhance the plywood’s durability and resistance to sunlight or moisture.Quality Control

Finally, the bamboo panels undergo a rigorous quality control process to ensure they meet the required standards for durability, appearance, and environmental impact. Only then are they ready to be packaged and shipped for use in home construction, furniture, or decoration.Packaging and Shipping

The final products are carefully packaged to avoid damage during transportation and then shipped to various distributors, woodworking shops, or directly to consumers for a wide range of uses, from cabinetry to flooring.

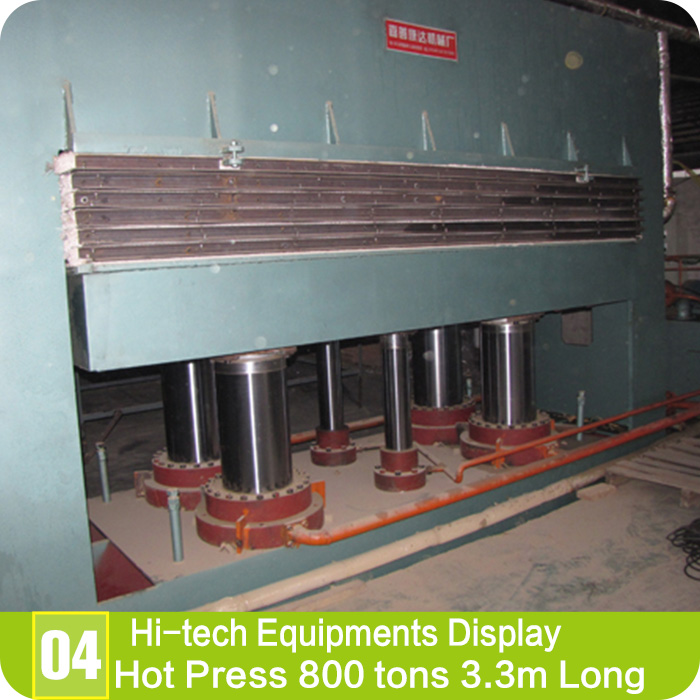

Some key machines for producing bamboo panel.

A hot press machine applies both heat and pressure to bond the bamboo strips together. The heat activates the adhesive, ensuring a strong and durable bond between the strips.

A cold press machine relies solely on pressure to bond the bamboo strips together. While heat is not applied, the pressure must be maintained for a longer period to ensure the adhesive fully cures and the strips are firmly bonded.

A sanding machine for bamboo panels works by using abrasive materials to smooth the surface of the bamboo, removing imperfections, evening out the texture, and preparing the panel for finishing treatments like staining, sealing, or painting.

Bamboo panels represent a versatile, sustainable material choice that aligns with contemporary trends towards eco-friendly construction and design practices. Their unique combination of durability, aesthetics, and environmental friendliness makes them a popular choice across a range of applications.

Bamboo Panels Uses

Furniture

Bamboo panels are widely used in the construction of furniture due to their strength and aesthetic appeal.Wall Cladding and Ceiling Panels

Bamboo panels can add a natural and exotic touch to interior designs when used for wall cladding or ceiling panels.Counter Tops and Work Surfaces

The durability and moisture resistance of bamboo panels make them suitable for kitchen countertops and other work surfaces.Decorative Elements

Due to their appealing texture and finish, bamboo panels are also used for decorative purposes, including picture frames, lampshades, and accent pieces.

皖公网安备 34180202000049号

皖公网安备 34180202000049号