How to Produce Bamboo Decking

Feb 7, 2026, 18:30 PM

When you walk in the park, you can see decking installed in some places like walkway, terrace, platform etc. Bamboo decking has a huge demand in recent 10 years because of its stable quality and beautiful texture. The production process includes bamboo treatment, long time carbonization, heavy pressing and oiling etc. Bamboo decking is manufactured through a series of steps designed to transform the raw bamboo plant into a strong, durable, and aesthetically pleasing decking material. Below is a detailed description of the manufacturing process.

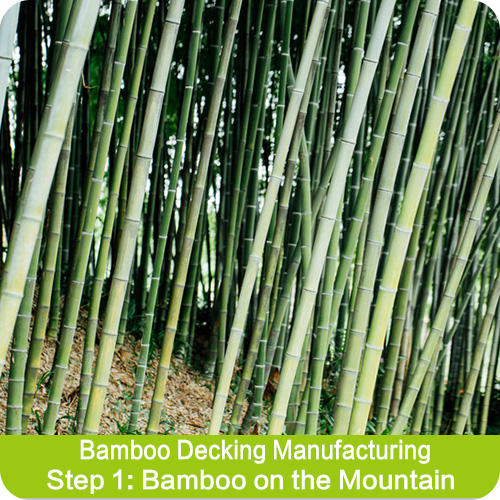

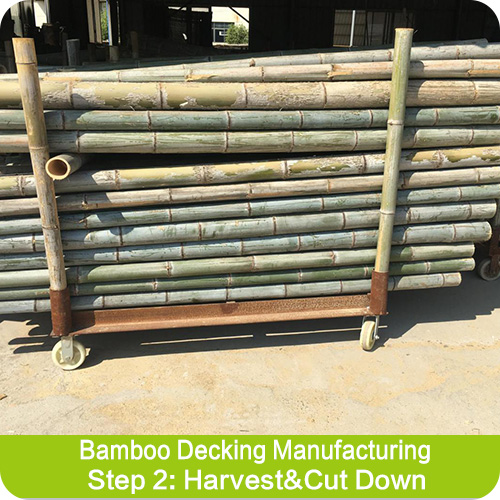

Harvesting:

Bamboo used for decking is typically harvested from managed forests where it has been allowed to mature for around 3 to 5 years. At this age, bamboo reaches its peak strength. Harvesting is done carefully to ensure the sustainability of the bamboo forest, with new shoots continuously growing to replace the harvested poles.Dividing:

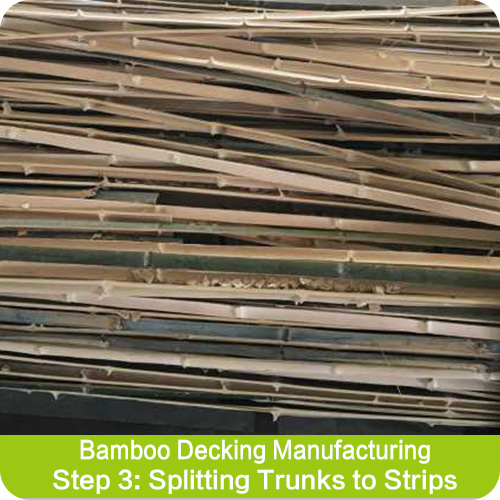

Once harvested, the bamboo poles will be cut into bamboo trunks in 2m length per piece.Cross-Cutting and Splitting:

The bamboo trunks are then split into thinner slats known as staves. These staves form the basis of the decking boards.Knots Removing:

All bamboo strips will go through a machine to remove the knots, then the strips will get flat and same size.Crushing:

This is a very key step, the density of strips is only 0.7kg/m3, We need increase the density by a physical way – crushing the strips, destroying the original structure. After crushing, the strips come to be fibers.Boiling and Carbonizing:

The bamboo staves undergo a boiling process to remove sugars and starch, which helps prevent insect infestations and decay. Then they will sent into a carbonization pot with hot steam over 4 hours to make the color much darker. It entails heating the bamboo under controlled conditions, which darkens it by caramelizing its natural sugars, giving the decking its distinctive color.Soaking the Glue:

We make a big and deep iron trough and put glue inside, then bamboo fibers will go inside for soaking the glue in a hanging way.Drying:

After soaking, the fibers will go through a dry tunnel to get a very low moisture content. Proper drying is essential to prevent shrinkage or expansion after installation.Pressing:

Our presser is 2500 tons with 13 layers, one press can produce over 40m2 of decking, one day can do at least 40 times of press. The pressed board size is 1870x1300x23mm.Conditioning:

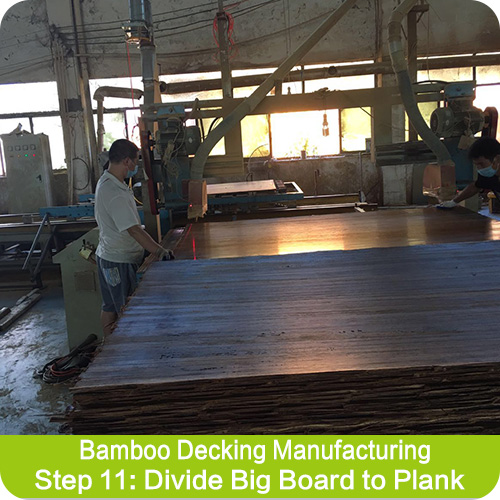

All pressed boards will be conditioned over 30 days to release the stress of fibers.Dividing:

The big size of board will be split into decking plank size – 1870x148x23mm or 2200x140x23mm.Milling:

We can offer 4 different styles in the milling of decking plank, the bottom side is always flat, the face side can be big wave, small groove, small ripple and flat. If you have a special request for the profiles, we are OK to make a special knife for your orders.Oiling:

All decking planks are pre-oiled in the factory, it is German-produced natural oil. We offer 10-year-warranty for our pre-oiled decking because we have strong confidence for our oil, the oil is another key for manufacturing a good quality of bamboo decking.Packing:

The standard packing is 5 planks per bundle, if you need cartons, of course, we can do it. Then we put the decking on the pallets for quick container loading.Delivery:

We always carry a big stock of bamboo decking in different styles, we do worldwide shipping by container to distributors and retailers.

The entire manufacturing process of bamboo decking is monitored to ensure that it is environmentally friendly and that the end product is structurally sound, aesthetically pleasing, and long-lasting. As demand grows, we continue to innovate, improving the efficiency, quality, and sustainability of their processes to meet customer expectations and environmental standards.

皖公网安备 34180202000049号

皖公网安备 34180202000049号